Technologies used by the company

The use of state-of-the-art technologies in the production and management process is a strategic choice for Surgenuin.

Since the early years an important effort has been made to adopt the best technologies that in some cases have also led to the creation of innovative solutions.

-

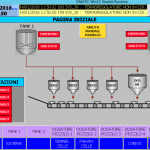

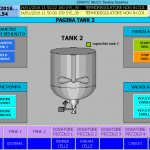

A computerized cooking system using diathermic oil, which allows any kind of cooking even without the constant supervision of the staff.

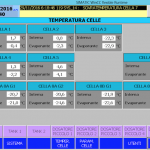

For each stage of the recipe, a dedicated temperature management curve is studied and developed, to automatically regulate, manage and optimize the cooking process.

-

IQF (Individually Quick Frozen) freezing plant, unique in its kind, designed, built and certified by Surgenuin itself.

The plant allows to obtain product lots that are easy for consumers to cut up into portions, easy and quick to prepare.

The first step of freezing occurs at -110 °C, ensuring immediate cooling of the product without damaging the structure of the food and preserving all the organoleptic and nutritional characteristics of the product.

-

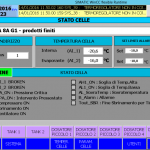

A system that manages, controls and tracks the production process, constantly monitoring the parameters provided by machinery and refrigeration cells.

-

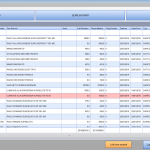

Computerized HACCP and tracing management system that allows staff to handle recipes, raw materials, minimum stocks and the process in the course of the production simply using a tablet.

All systems are integrated with each other in order to guarantee the complete and instantaneous availability of both process and product information at any time and for each batch of production, allowing in a matter of seconds to fully trace the batches of raw materials used, the production process data and the list of customers to which each batch of finished product was delivered.